Advanced Materials Testing & Analytical Services

Providing professional chemical composition testing, material analysis, and formula reverse engineering services to support R&D, quality assurance, and competitive product development.

Typical Application Scenarios

Competitor Benchmarking

Understand how competitor materials and products are formulated and why they perform differently. We analyze composition, additives, fillers, microstructure, and key performance indicators to support product optimization, cost reduction, and competitive differentiation.

Typical needs include:

Comparing formulations and material grades

Identifying performance gaps and improvement opportunities

Supporting new product development and positioning

Defect & Failure Investigation

When products fail, discolor, crack, delaminate, or lose performance, rapid root-cause identification is critical. We combine materials testing, chemical analysis, and microscopy to determine failure mechanisms and prevent recurrence.

Typical needs include:

Cracking, brittleness, or premature aging

Adhesion failure or layer separation

Surface defects and contamination

Unexpected mechanical or thermal property loss

Quality & Supplier Qualification

Ensure consistency, reliability, and compliance of raw materials and finished products. Our testing and impurity analysis help verify supplier materials, detect hidden contaminants, and monitor batch-to-batch variation.

Typical needs include:

Incoming material inspection

Supplier comparison and approval

Impurity and contamination screening

Long-term quality monitoring

Our Services

Materials Testing

Mechanical, thermal, chemical, and physical property evaluation of materials.

Compositional Analysis

Determine ingredients, additives, fillers, and ratios using advanced analytics.

Deformulation

Break down complex formulations and reconstruct processing/material insights.

Failure Analysis

Root-cause investigation of defects, cracking, corrosion, and performance loss.

Impurity Analysis

Detect and quantify trace impurities impacting quality, safety, and reliability.

Surface Analysis

Surface morphology and chemistry analysis for coatings, adhesion, and interfaces.

Composition & Materials ID

Identify unknown materials, foreign particles, or contamination sources.

Materials Characterization

In-depth characterization to support R&D, benchmarking, and optimization.

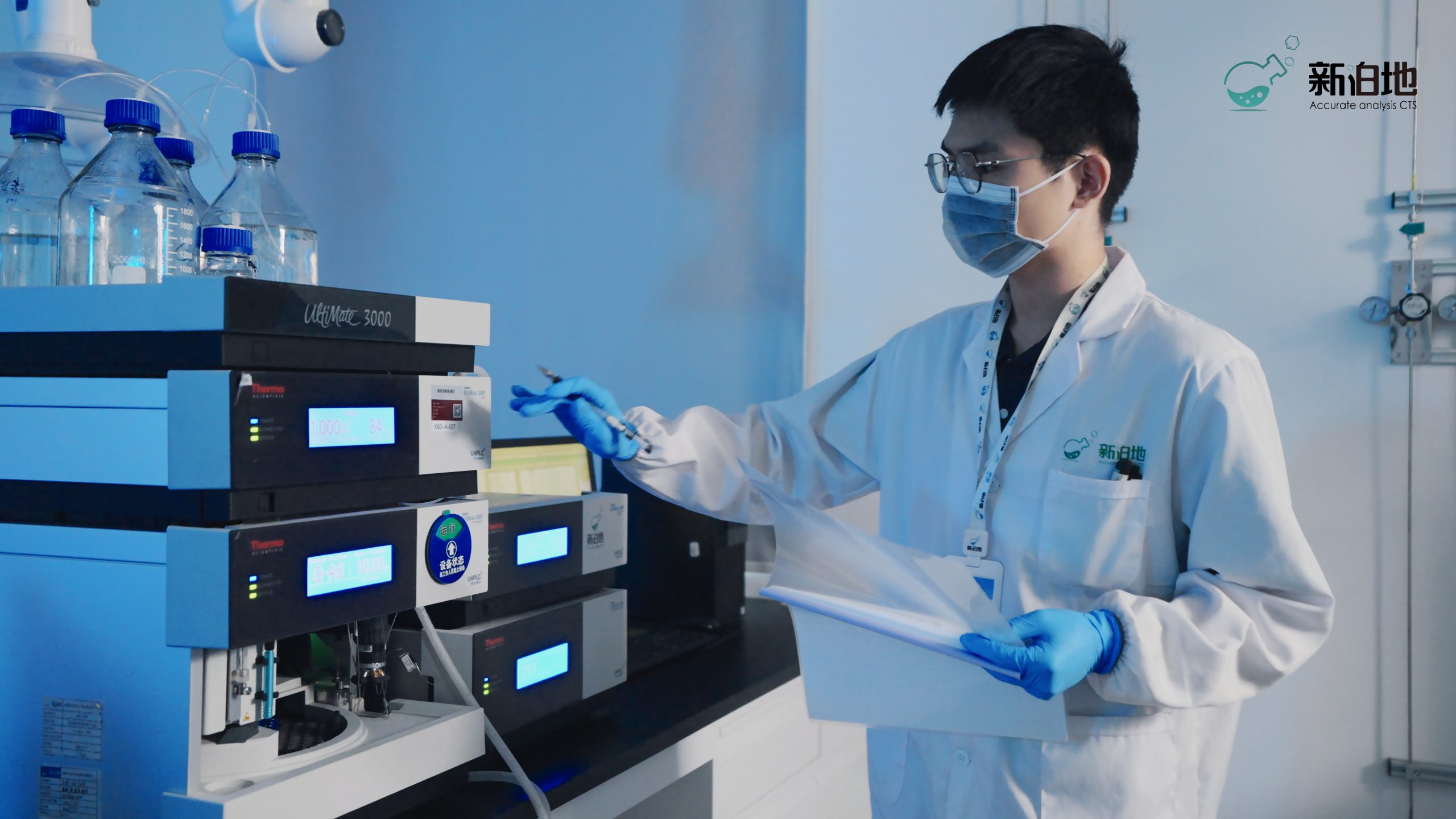

Welcome to xinbodi Laboratories

Shanghai Xinbodi Materials Research Co., Ltd., founded in 2015 and headquartered in Shanghai, is China’s pioneer of the Materials CRO model, specializing in chemical and advanced materials innovation. Xinbodi delivers end-to-end testing, analysis, reverse engineering, CRO+CDMO and IP services across semiconductors, new energy, polymers, coatings, medical and fine chemicals, empowering global R&D success.

Why Choose Xinbodi Laboratories

- Advanced analytical instruments covering spectroscopy, chromatography, microscopy, thermal and mechanical testing.

- Experienced materials science team providing expert interpretation and engineering insights.

- Comprehensive capability from routine QC testing to deep-dive troubleshooting and reverse engineering.

- Fast turnaround & flexible scope with customized testing plans for your project goals.

- Clear, structured reports including raw data, graphs, conclusions, and recommendations.

- Confidentiality & data security for proprietary materials, formulations, and IP-sensitive projects.

Advanced Testing Capabilities

We design testing programs that align with your material type, application environment, and target standards. Below is a representative capability map.

Mechanical Testing (tensile, hardness, impact)

Thermal Analysis (DSC, TGA, DMA)

Spectroscopy (FTIR, Raman)

Chromatography & MS (GC-MS, LC-MS)

Microscopy (SEM/EDS)

Elemental Analysis (ICP, XRF)

Structure Analysis (XRD)

Rheology & Viscosity

Typical deliverables

Reports are structured for engineering decisions and internal documentation.

- Methods, conditions, and instrument details

- Raw data tables, graphs, and micrographs

- Interpretation, conclusions, and recommendations

- Optional comparison to target specs or competitor materials

Industries We Serve

Service Process

Communicating Needs

Communicate your needs with the engineer and schedule a lab visit.

Sampling

Send samples or have the engineer collect samples on-site, and sign a contract.

Sample Analysis

The sample will be analyzed and tested using instruments, and the engineer will compile a data report.

Report Delivery

The report will be delivered, and the engineer will proactively follow up to resolve any after-sales questions.